We are the No.1 brand in the manufacturing of liquid nitrogen generation plant with world-class standards of quality. Our company follows the globally accepted GMP (good manufacturing practices) for turning out the best quality air separation products. As you might be aware nitrogen constitutes around 78% of the atmospheric air. However, the industries need greater purity up to 99.9% which we obtain through industrial machinery. BDM Export builds & supplies liquid nitrogen generators for construction, medicine, food packaging, food preservation, manufacturing, soldering and for creating modified atmosphere. Our N2 products are performing extremely well all over the world. Our single focus is to manufacture & deliver machinery trusted for reliability, durability and efficiency.

First and foremost, we make our LIN plants with the ASME quality materials. As the plants run on the cryogenic technology it is important that the solid materials are used in their fabricating. At extreme temperature and pressure, there is a greater tendency for rapid wear and tear. So there is a need for using materials that can withstand such conditions. However, we place the top priority to building air separation column with cryogenic grade stainless steel because the entire performance of the plant depends on the quality of column. Argon welding is used in the fabrication for precision and efficiency. Since our products comply with European quality stands, we procure components and parts only from the leading European OEMs.

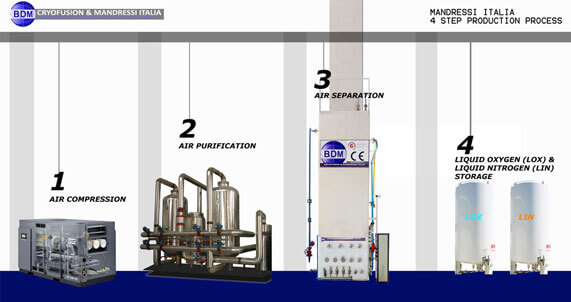

Typically, liquid nitrogen plant working principle is able to generate liquid nitrogen through liquefaction of atmospheric air and separation of nitrogen in the high pressure distillation column. Afterwards, the chosen product is sent into the low pressure distillation column for achieving the desired purity. In technical terminology, the process is known as cryogenic or fractional distillation. No denying it is the most efficient and production techniques available in the air separation industry. Medium to large industries go for using cryogenic air separation technology for onsite production of oxygen or nitrogen. There are other technologies available as well but none matches the effectiveness of cryogenic low pressure technology.

We have been in the air separation industry for three and half decades cementing the reputation of BDM brand. Brand consolidation is a slow process that demonstrates consistent delivery of quality products. Our liquid oxygen generation plant, liquid nitrogen plant generation system enjoys immense brand reputation because of its quality and performance. We design and fabricate the systems for maximum utilization, performance and efficiency. The systems installed worldwide have been working satisfactorily for decades. The industry-proof of reliable performance and long life-cycle explains the leading place the company has made for itself. All of our air separation systems are fully automated with PLC systems from Siemens.

Liquid nitrogen (LIN) is widely used in the various industries. In the day-to-day life, you will find that industries such food packaging & storage, aerospace, chemicals, metallurgy, etc, use LIN for running their operations. Instances of uses of liquid nitrogen filling plant includes shrink welding of machinery, beer production, making ice cream, biological sample preservation, cryosurgery, and so forth. Most of these industries like to opt for installation of liquid nitrogen plant for reliable generation of nitrogen for fulfilling your requirements. Using BDM’s nitrogen plant is that you get to use high precision industrial machinery for providing you with uninterrupted supply of 99.9% pure nitrogen.

| MODEL | LIQUID NITROGEN CAPACITY | PURITY OF NITROGEN | |

|---|---|---|---|

| BDM L-50 | 55 Liters / hr | 1.5 Tons per day | 99.9% |

| BDM L-80 | 90 Liters / hr | 2.5 Tons per day | 99.9% |

| BDM L-100 | 100 Liters / hr | 3 Tons per day | 99.9% |

| BDM L-150 | 180 Liters / hr | 5 Tons per day | 99.9% |

| BDM L-200 | 215 Liters / hr | 6 Tons per day | 99.9% |

| BDM L-250 | 290 Liters / hr | 8 Tons per day | 99.9% |

| BDM L-300 | 360 Liters / hr | 10 Tons per day | 99.9% |

| BDM L-400 | 425 Liters / hr | 12 Tons per day | 99.9% |

| BDM L-500 | 540 Liters / hr | 15 Tons per day | 99.9% |

| BDM L-1000 | 1170 Liters / hr | 30 Tons per day | 99.9% |

| BDM L-1500 | 1755 Liters / hr | 45 Tons per day | 99.9% |

| BDM L-2000 | 2340 Liters / hr | 60 Tons per day | 99.9% |

| BDM L-3000 | 3515 Liters / hr | 90 Tons per day | 99.9% |

| BDM L-4000 | 4685 Liters / hr | 120 Tons per day | 99.9% |

| BDM L-5000 | 5850 Liters / hr | 150 Tons per day | 99.9% |