We are leaders in manufacturing and fabricating cryogenic air separation plant with superior cryogenic technology. Cryogenic air separation is a technique for separating the desired gas from the other gases present in the atmospheric air. There are other techniques available in the industry such as PSA, VPSA and membrane separation. However, the adsorption technologies are not as effective and efficient as cryogenic distillation. Besides, oxygen or nitrogen purity generated through PSA plants drops significantly within 6 months of operation. On other hand, cryogenic air separation plants generate oxygen with purity of 99.7% and nitrogen with purity of 99.9%. And their efficiency and effectiveness remains intact year after year. They have got life cycle of over 25 years.

We are a trusted brand for manufacturing air separation generation plants with top-notch cryogenic distillation technology. Our brand has been gaining traction over a period of 35 years by virtue of our commitment to make high quality products. Satisfaction of clients is the top priority for us with our designing and manufacturing geared to achieve the same. It is on the strength of the quality of our air separation products that we have become the preferred brand in the industry. Our fabrication is carried out in compliance with GMP (good manufacturing practices) and European quality standards.

Our manufacturing and fabrication is completed with the best quality materials. During this stage, we test the materials for strength to ensure they could withstand extreme wear and tear and perform for years. Obviously, the average life cycle of our air separation products is over 25 years. Some of the plants we installed at the start of our business are still running strong. Needless to say, the trust of the customers is of paramount importance to us. We employ the best processes, techniques, materials, components and parts in the fabrication. Air separation oxygen generation plant column is made with high grade stainless steel welded with argon.

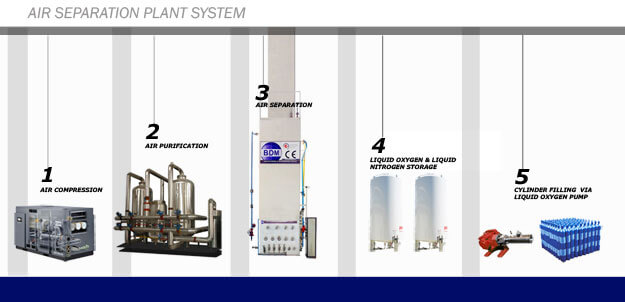

BDM Export cryogenic air separation production plant process is cutting-edge in its scope and performance. The air separation process begins with taking atmospheric air, which is then filtered and compressed. Afterwards, the air is cleaned from impurities such as carbon dioxide, water content, and hydrocarbons. Then, the air is put through a series of heat exchangers for liquefaction at cryogenic temperatures. After liquefaction, it is moved into a high pressure distillation column. Here, the air is separated into its constituent gases including oxygen, nitrogen and argon on the basis of their boiling points. The desired gas is collected and sent into a low pressure distillation column for achieving the specified purity. BDM Export is most trusted company of cryogenic storage tanks manufacturers in India like oxygen, nitrogen, argon, liquid tanks & gas tanks.

BDM Export is very particular about the quality and costing of our products. Our air separation unit system price is the most competitive in the industry. No other air separation generation plant manufacturer can match our prices and quality. Our brand leads the market by virtue of high quality and the best costing. Manufacturing of oxygen gas generation plant and nitrogen generation plant, air separation products is completely finished with world-class materials that can withstand the ravages of daily wear and tear. For example, we build the air separation columns with high grade stainless steel with argon welding. The column is the most important part of an air separation generation plant and accounts for almost 60% of the pricing.

| MODEL | CAPACITY | CYLINDERS FILLED PER DAY | OXYGEN PURITY | NITROGEN PURITY Optional |

|---|---|---|---|---|

| BDM 50 | 50 m3/hr | 200 | 99.7% | 99.99% |

| BDM 80 | 80 m3/hr | 320 | 99.7% | 99.99% |

| BDM 100 | 100 m3/hr | 400 | 99.7% | 99.99% |

| BDM 130 | 130 m3/hr | 500 | 99.7% | 99.99% |

| BDM 150 | 150 m3/hr | 600 | 99.7% | 99.99% |

| BDM 170 | 170 m3/hr | 680 | 99.7% | 99.99% |

| BDM 200 | 200 m3/hr | 800 | 99.7% | 99.99% |

| BDM 250 | 250 m3/hr | 1000 | 99.7% | 99.99% |

| BDM 300 | 300 m3/hr | 1200 | 99.7% | 99.99% |

| BDM 400 | 400 m3/hr | 1600 | 99.7% | 99.99% |

| BDM 500 | 500 m3/hr | 2000 | 99.7% | 99.99% |

| BDM 1000 | 1000 m3/hr | 4000 | 99.7% | 99.99% |

| BDM 1500 | 1500 m3/hr | 6000 | 99.7% | 99.99% |

| BDM 2000 | 2000 m3/hr | 8000 | 99.7% | 99.99% |

| BDM 3000 | 3000 m3/hr | 12000 | 99.7% | 99.99% |

| BDM 4000 | 4000 m3/hr | 16000 | 99.7% | 99.99% |

| BDM 5000 | 5000 m3/hr | 20000 | 99.7% | 99.99% |